From Lean Connectivity to Lean Automation New Eaton HMI/PLCs Integrate SmartWire-DT Master

Eaton’s Electrical Sector, one of the leading manufacturers of components, systems and solutions for electrical engineering and automation, is launching new XV102 touch display PLCs which offer a high-performance HMI/PLCs with an integrated SmartWire-DT master. SmartWire-DT is a comprehensive connection and communication technology from Eaton: The uniform and open system replaces the control wiring in all components, from the circuit-breaker to motor starters and frequency inverters, right through to pilot devices and sensors.

Photo: Eaton Corporation

The new XV102 device series with a SmartWire-DT master is based on the XV100 HMI/PLC and stands out on account of its compact dimensions and high performance: This is provided by a 400 MHz RISC processor and a 128 MB on board memory (also expandable as required with an SD memory card). All HMI/PLCs can also handle demanding PLC applications.

The SmartWire-DT master integrated in the device is a new feature: Previously, the connection required a gateway which was linked to the XV100 HMI/PLC via CANopen or Profibus. Eaton has now elegantly and efficiently designed the SmartWire-DT interface, and has integrated the master directly in the touch panel. Eaton plans to launch five XV102 HMI/PLCs with SmartWire-DT master this year. The following display sizes and interfaces are available: A 3.5 inch as well as 5.7 inch and 7 inch screen with RS485 and CANopen or Profibus DP/MPI.

This SmartWire-DT master integration offers several user benefits. The SmartWire-DT line can be configured simply and conveniently via CoDeSys. The technical data of the SmartWire-DT interface is the same as that of the previous SmartWire-DT gateways, i.e. users can access the full range of functions and can connect up to 99 slaves to a SmartWire-DT master. In line with the “Connecting instead of wiring” principle, the SmartWire-DT interface connects all the way into the PLC without the use of an intermediate circuit. Users also save the additional device costs of a separate cabled gateway.

Eaton is covering a wide application range with the five XV102 HMI/PLC variants. The 3.5 inch device together with SmartWire-DT pilot devices, motor starters, contactors and remote SmartWire-DT I/Os is suitable for compact lean automation solutions. The 5 inch and 7 inch devices are ideal for medium-sized machines and systems. As well as having SmartWire-DT, two standard fieldbuses, either Profibus DP and CAN, allow devices with standard fieldbus interfaces to be integrated in the automation concept.

Like all visualisation devices of the xSystem product groups, the XV102 series HMI/PLCs can be programmed with the Galileo visualisation software or CoDeSys visualisation software, and programmed as a PLC with the CoDeSys-based xSoft-Codesys-2 programming system in accordance with IEC61131-3. Thanks to their small mounting depth, the panels can also be installed in confined spaces. All display fronts can be customised if required. XV102 devices support the trend towards scalable hardware and software solutions that allow machine and system builders to keep the requirements for engineering and system maintenance to a minimum. The XV102 series also supports the requirements for a modular machine design.

Photo: Eaton Corporation

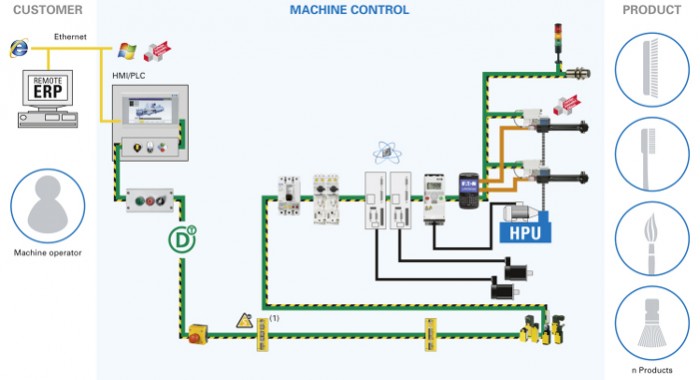

This visionary “lean automation” structure developed by Eaton eliminates the need for remote I/Os and any signal wiring to sensors or actuators. Lean connectivity takes the SmartWire technology directly into the devices, as is clearly demonstrated on the XV102 series. The structure consists of an HMI/PLC with integrated SmartWire-DT and components with remote intelligence. Starting from the panel, SmartWire-DT connects pushbutton actuators, indicator lights, and switchgear right up to the sensors. Frequency inverters and safety systems, as well as hydraulic and electrical drives are also gradually being integrated via SmartWire-DT. “Lean automation” finally brings together the world of hydraulics and the world of electrics in the automation world.

Get more info about the Lean Technology on the online exhibition stand of Eaton on EXPO21XX.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech