Mitsubishi Adroit Process Suite (MAPS) is now launched in Scandinavia

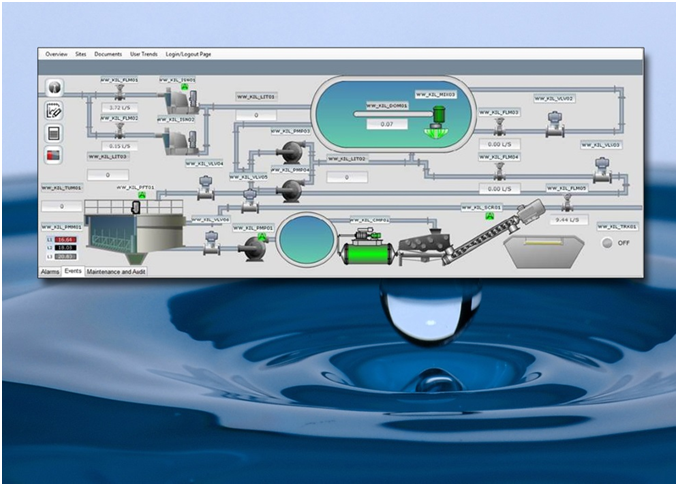

The life-cycle management tool MAPS can be used for complex process-oriented solutions, as a normal SCADA/HMI or even for an OEM wanting a panel-based HMI solution.

Photo by Mitsubishi Electric Europe. B.V.

Mitsubishi Electric has launched MAPS (Mitsubishi Adroit Process Suite) in the strategically important regions of Scandinavia and the Baltic States.Mitsubishi explains that MAPS offers much more than a simple SCADA system. It is a complete life-cycle management tool. One of its main benefits is almost infinite scalability: MAPS can be used for complex process-oriented solutions, as a normal SCADA/HMI or even for an OEM wanting a panel-based HMI solution.

MAPS hasrecently been introduced to Mitsubishi systems integrators and customers throughout Scandinavia by a series of roadshows, where it was extremely well-received. Bjorn Sandberg, Scandinavian technical support engineer for Mitsubishi Electric Europe’s Factory Automation Group, says: “Delegates appreciated that its’ easy to use, intuitive design interface makes building solutions very easy.”

As a life-cycle software tool, it performs along the entire value chain and, unlike PLC/ SCADA integration tools, is usable in both the engineering and integration phases. Its scalability means system extensions are easily accommodated, while maintenance is straightforward, thanks to its flexibility.

One of the keys to MAPS’ popularity is its PLC/SCADA wizard function, which significantly reduces the time spent on development and configuration. It also ensures a standardised and structured design, which eases ongoing maintenance of the plant throughout its life cycle.

With MAPS, reports covering areas such as I/O schedules, PLC and SCADA tag configuration can be automatically generated. This ensures drawings and reports are always up to date. The reports are database-driven, so even through ongoing maintenance the reports will always reflect the current status of the electrical and instrumentation configuration.

Bjorn Sandberg summarises the benefits of MAPS as:

• Single point of configuration, deployment and management

• Automatically generated PLC and SCADA projects to reduce engineering effort

• Automatically generated reports

• Ongoing life-cycle management

He says: “MAPS can fit any size solution as systems are built up from the I/O requirement and number of HMIs needed. Users can start small and can easily scale up later on.”

Overall, MAPS provides the customer with an innovative and integrated life-cycle management tool, which dramatically reduces the engineering time and cost throughout the lifetime of a plant. The software offers full flexibility from engineering to system integration for almost every customer demand. This makes it ideal for applications in a huge range of industries, and especially well suited to water and waste water, mining, food and beverage and life science.

For more information, please visit http://eu3a.mitsubishielectric.com/FA.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech