More order in a small space with the new chainflex CASE S cable box from igus

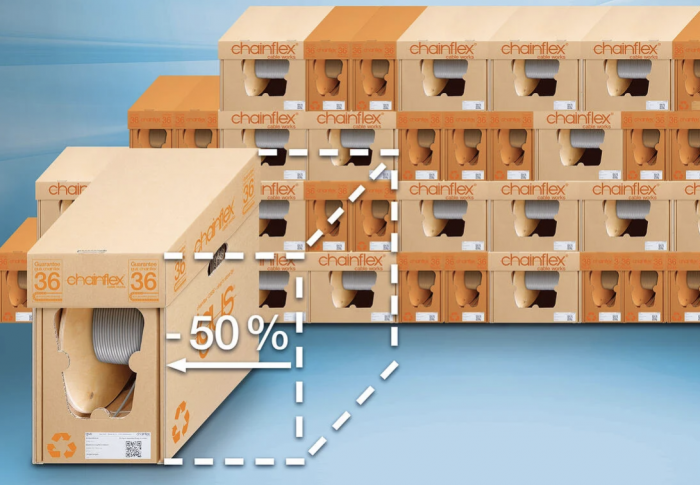

In order to be able to store and transport as much as possible in a small space, better and better logistics solutions for cable reels are being sought. Thanks to the new chainflex CASE S from igus, lack of space in the warehouse is a thing of the past. The cable box is a supplement to the larger CASE M and also enables cables to be easily reeled off directly from the box – even when on the move. With the smaller CASE S, storage and transport is now even easier. This is because customers save 50 percent storage space while retaining 100 percent of the benefits.

With the CASE M, the motion plastics specialist igus has already developed a special logistics solution for its chainflex cables in 2020, so that users can save both shipping and storage costs. The chainflex CASE is a cardboard box made of 100 percent recyclable materials that enables drum shipping without a pallet. This means that the goods can be shipped using a parcel delivery service. At the same time, the CASE serves as a storage system for cable reels. The chainflex cables can be unwound directly from the box and cut to the desired length. Setting up a space-saving storage system for cable reels quickly and cost-effectively is now even easier thanks to the new chainflex CASE S. “We have noticed that there is additional demand on the market for a more compact solution for the storage and transport of cable metre goods. For thin cables or shorter cable lengths, for example,” explains Andreas Muckes, Head of Product Management chainflex cables at igus. “That is why we are now offering a new, smaller size of our cable box in the form of the CASE S. This saves us 50 percent of the packaging effort and users need 50 percent less storage space for their reeled goods.”

Easy handling – even on the road

With chainflex CASE M and S, customers do not need any racking system to hang up their cable reels. Since both sizes are compatible with each other, customers can easily stack the cable boxes on top of each other and thus set up flexible storage facilities. With the smaller CASE S, storage space can now be used even more effectively. In addition, with shorter cable lengths, users also save in terms of costs compared to the chainflex CASE M with a maximum filling of 200 metres. The compact size also pays off when on the move. The chainflex storage system is mobile and, thanks to the smaller size, can now be transported even more easily in the car and can also be used directly on construction sites, for example. The chainflex CASES are already a popular logistics solution, especially for service technicians and in the service area of factories. In contrast to cable routing with a ring, the stored drum enables twist-free cable filling of the energy chain, which is the basis for a long service life in the e-chain.

Reordering via QR code

If the metre-long product is used up at some point, customers can reorder their cables on the web in just a few seconds using their smartphone – simply by using the individual QR code on the shipping carton. This not only saves customers shipping and storage costs, but also process costs. A total of over 850 cables are available in the chainflex CASE. With the chainflex range, customers receive flexible and robust cables that defy diverse applications with enormous speeds and accelerations, long travel distances and the most adverse environmental influences. In numerous tests in our own 3,800 square metre test laboratory, the cables continuously prove their durability. Based on this data, their service life can also be precisely calculated – in just a few clicks using an online tool. “Thanks to the results of our extensive tests and our more than 30 years of experience, we can also give our customers a guarantee of up to 36 months or 10 million double strokes on our cables with a clear conscience. We were the first German company to have this promise validated by the globally respected testing organisation “Underwriters Laboratories” (UL),” adds Andreas Muckes.

For more information, please visit: https://www.igus.de/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech