New “Weld Navigation” function of the TAWERS technology provides easier and faster development

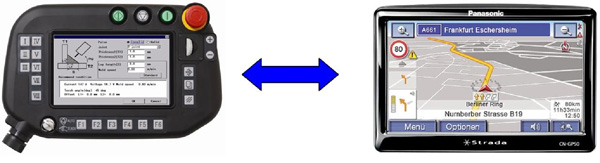

Panasonic Robot and Welding Systems Europe are proud to present the newest function to allow easier and faster welding, as part of the established TAWERS robot systems with integrated welding power source technology. This latest feature, referred to as “Weld Navigation”, can be compared to a navigation system in the car. It guides the user in the parameter choice utilising a range of “on screen” information data pages ensuring the required welding target is realised.

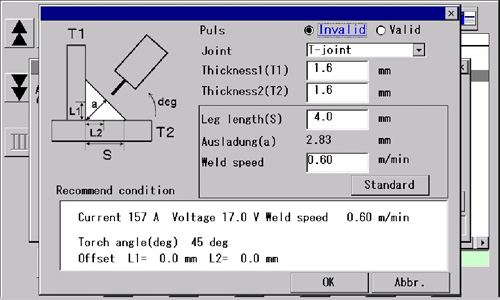

To find the best welding parameter for the application you need only to select joint type and material thickness. The remaining parameter will be automatically calculated by the configured synergy curve and welding speed. Additionally it’s possible to influence the design of throat thickness or joint length to adjust the joint design to specialised requirements. “Weld Navigation”, will automatically re-calculate the new parameter instantly.

New opportunities are now created allowing less experienced programmers with limited welding knowledge to seek and achieve perfect welding results within a short time. It will also allow the welding “expert” to reduce routine remedial work enabling them to concentrate their skill and know-how on product optimisation.

You can see on the following picture how easy it is to adjust the specification. According to the joint only the necessary specifications will be queried or requested:

Now by utilising the “Weld Navigation”, there is a high quality tool available to support the professional user.

The function complements the proven TAWERS technology allowing modern arc processes to increase productivity, avoiding spattering, ensuring process stability while saving energy.

The TAWERS benefits can be detailed as:

AWP – Active Wire Process

- HS – Hyper Stabilization

- Hyper Dip Pulse

- MTS-CO2 – Metal Transfer Stabilization CO2

- SP-MAG – Super-Imposition MAG

- MAG-Heat

More details are available at: http://www.panasonicrobotics.eu

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech