Nikon’s AI Reconstruction uses Deep Learning for quicker, sharper CT scans

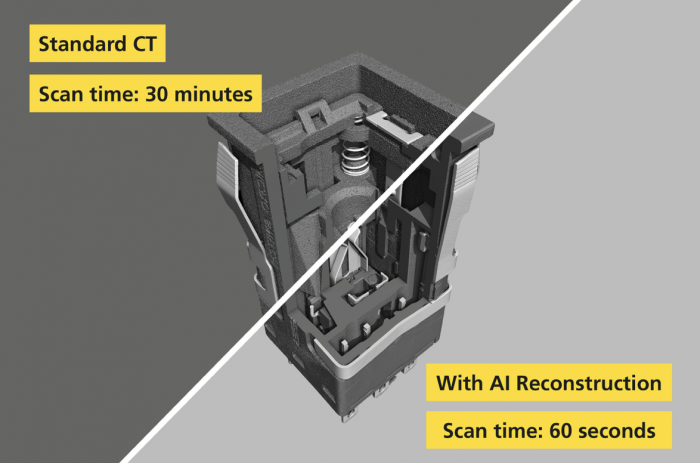

Nikon IMBU has introduced AI Reconstruction, an innovative software solution for 3D computed tomography (CT) scans, leveraging artificial intelligence to overcome the traditional trade-off between scan speed and image quality. By employing Deep Learning techniques, Nikon’s groundbreaking technology ensures swift results and enhanced analysis, eliminating the need for users to compromise between speed and quality.

Traditionally, users had to choose between fast, lower-quality scans or slower, higher-quality scans, leading to missed details or reduced scanning capacity. With AI Reconstruction, Nikon’s Applications Engineering team tailors AI enhancement to meet individual customer needs, training Deep Learning models to filter noise and improve clarity by distinguishing relevant information from scan artifacts.

According to Chris Price, Product Manager for X-ray & CT Systems at Nikon, this advancement represents a significant shift in industrial computed tomography, offering rapid results and superior image clarity without sacrificing speed, thereby enabling testing and quality teams to enhance throughput and precision while uncovering minute product flaws with greater efficiency than ever before.

Revolutionizing Quality Control

This technology is poised to have a significant impact in sectors such as automotive, aerospace, manufacturing, and medical devices, where meticulous quality control is critical for product safety. Nikon’s breakthrough has been rigorously validated, offering flexible integration with leading analysis packages for inspecting complex component geometries.

Compliant with the European Union’s Ethics Guidelines for Trustworthy Artificial Intelligence, AI Reconstruction ensures human oversight, technical robustness, privacy, transparency, diversity, non-discrimination, societal well-being, and accountability. Developed on the same Deep Learning AI as Nikon’s LiB.Overhang Analysis, AI Reconstruction enhances image quality for broad applications, unlike the analysis-focused LiB.Overhang Analysis.

While LiB.Overhang Analysis precisely analyzes anode overhang in lithium-ion batteries during mass production, AI Reconstruction improves image quality to facilitate analysis using industry-standard software. Nikon’s tailored service for AI Reconstruction involves direct collaboration with clients to train accurate models based on their workflow samples.

Initially targeting LiB cell production, Nikon aims to enhance evaluation productivity on lithium-ion battery assembly lines, meeting the growing demand for automated quality control in next-generation transport manufacturing. Existing customers are being informed of AI Reconstruction’s benefits, while new customers can contact their local Nikon Metrology representative for an introductory call and demo.

About Nikon Industrial Metrology

Drawing upon over a century of expertise in advanced opto-electronics and precision technologies, Nikon offers a diverse range of products, services, and solutions globally, striving to enhance both quality of life and manufacturing practices. Within Nikon’s Industrial Metrology Business Unit (IMBU), specialized in ultra-high precision solutions, the focus remains on delivering tailored, cost-effective solutions that seamlessly integrate and perform exceptionally from the outset. In a recent advancement within Nikon’s Digital Manufacturing initiative, IMBU has forged closer collaboration with the Digital Solutions Business Unit (DSBU), resulting in the introduction of optical additive and subtractive manufacturing solutions capable of processing various materials to achieve sub-micron surface finishes.

For more information, please visit: https://industry.nikon.com/en-gb/news/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech