Rittal’s new push-in conductor connection clamps offers most efficient method for connecting conductors to busbars

Photo by RITTAL GmbH

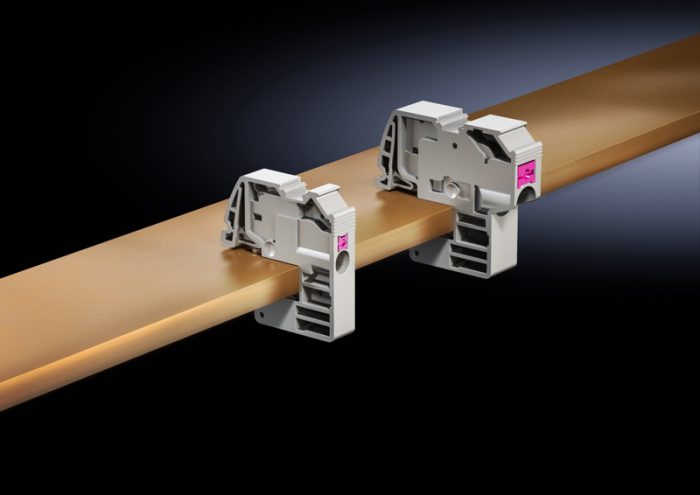

Wires and cables often have to be connected to copper busbars when manufacturing control gear and switchgear systems. The conventional approach is time-consuming and uses screw clamps or fixed conductor connection clamps. With a new generation of maintenance-free conductor connection clamps utilizing push-in technology, Rittal now offers the fastest method of easily and securely connecting conductors to busbars.

Push-in clamps have a whole host of advantages, including extremely quick and easy cable connection. The maintenance-free clamps can be used for many different types of conductors. Rittal has developed a new generation of conductor connection clamps so as to extend these benefits to busbar systems. This means panel builders and switchgear manufacturers will be able to connect cables and wires directly to busbars. The new push-in conductor connection clamps are available in two clamping ranges, 0.5 – 4 mm2 and 1.5 – 16 mm2, and for copper busbars 5 and 10 mm thick in each clamping range.

The push-in conductor connection clamps enable quick and easy attachment to the busbar. The stripped end of the conductor is connected to the busbar simply by pushing it into the clamping space. The initial benefits take effect as soon as the clamp is attached. For one thing, a separate spring mechanism holds the clamp in place on the busbar. For another, the spring optimises conductivity by removing oxide layers that have formed on the busbar. The integral contact block with its defined and raised contact points applies optimum contact pressure.

The second spring inside the clamp ensures secure clamping. Quick and easy insertion into the clamping space against the spring pressure is achieved for solid, multi-wire and ultrasonic welding conductors and also fine wire conductors with wire end ferrules. Designs with twin wire end ferrules can also be connected.

The new push-in conductor connection clamp can reduce potential defects such as incorrect compression/torques and clamp loosening. The maintenance-free design makes the system more reliable and cuts the costs of subsequent maintenance work.

The new push-in conductor connection clamp can be used for numerous applications, such as connecting protective and neutral conductors to busbars. Short circuit-resistant voltage taps on the copper bars of a main busbar system are a further area of use. It is also possible to make string distributors or distributor blocks with a large number of connector clamps for outgoing cables.

Thanks to its numerous UL and IEC certifications, the new conductor connection clamp is suitable for use worldwide. This new development is also suitable for use in maritime and offshore applications. It is currently tested by ABS, DNV-GL and LR, and approvals are planned to be completed by September.

For more information, please visit www.rittal.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech