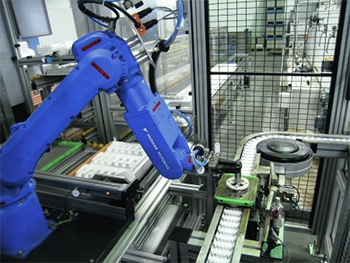

Innovative robot solution to produce shafts with MOTOMAN handling robots

The MOTOMAN handling robot MH5L inside the facility

Photo by SYMACON

The “KmB Technologie Gesellschaft für rationelle Fertigung mbH” company in the German city of Zerbst, has recently implemented an innovative robot automation solution. This comprises two interlinked robot cells each equipped with a MOTOMAN MH5L robot manufactured by YASKAWA.

The shaft is produced from a solid piece of material in a closed loop machining centre and subsequently transferred to the facility that has been designed and installed by SYMACON.

The facility can accommodate three different types of shaft whilst a purpose built work piece carrier links the two robot cells. In the first robot cell the shaft is measured. The robot is equipped with a double gripper so fast part exchange can be implemented reducing cycle times. When the robot has collected a shaft from the carrier, it transfers it to a measuring device. Various diameters, lengths and angles are measured and recorded for statistical purpose. Parts that are out of tolerance are placed separately depending on the error. Following successful measuring the robot returns the shaft to the work piece carrier. Following a subsequent cleaning process the shafts are finally packed in special trays in the second robot cell. Here the robot is equipped with a parallel gripper unit that places the shafts in the appropriate compartment of the tray.

MOTOMAN-MH5L handling robot

The implemented solution is the third of its kind supplied by KmB. Unlike previous installations that featured SCARA robots, SYMACON has selected articulated arm type robots, namely MOTOMAN MH5L handling robots. These 6 axes machines with a pay load of 5 kg belong to the new generation of MH series robots from YASKAWA. An improved reinforced wrist makes these robots the ideal choice for demanding and flexible applications such as packing, material handling, machine tending and dispensing. In addition these robots have a very compact design, which means that space requirements for installation are minimal. The integrated media and air supply maximise system reliability and reduce interference, which simplifies robot programming. Due to the special robot kinematics, additional swivel devices could be eliminated for this new facility thus also reducing cycle times. The „KmB Technologie Gesellschaft für rationelle Fertigung mbH“ company supplies the automotive industry with parts and assemblies such as steering components for various cars types.

For further information visit: www.motoman.de

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech