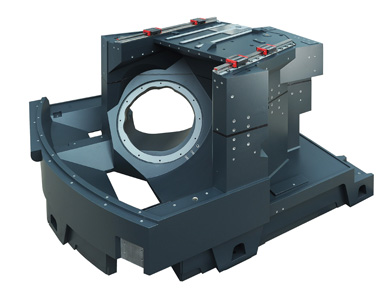

Schneeberger mineral casting parts offer decisive cost and benefit advantages

Photo by SCHNEEBERGER

Mineral casting is a multi-component material that is cast in the cold-casting process using accurately dimensioned negative forms. The components are – as stated in the name – minerals and binders, in our case an epoxy resin. The mineral part amounts to approximately 90% of the weight, the properties of this material therefore determine the final-properties of the product.

In contrary to metallic raw materials hardening causes very low shrinkage. This enables us to cast „near-net-shape“ machinery components requesting only final grinding or a precision molding process.

The use and cast-in of foreign materials, and joining together by gluing, are standard proceedings. The material has a lower stability than metal but offers other, additional and very interesting properties. Especially in the machine building industry, the use of such parts offers decisive cost/benefit advantages.

For further information, please visit: www.schneeberger.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech