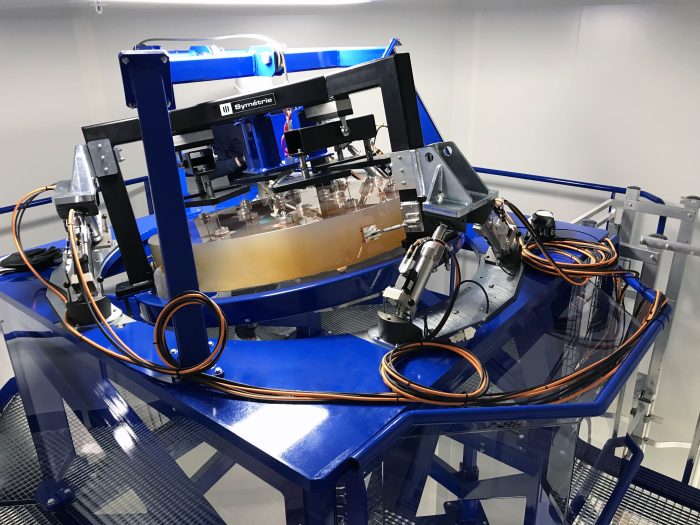

Four Symetrie hexapods are testing the 931 segments of the primary mirror of ESO ELT!

Operated by ESO, the European Southern Observatory, the Extremely Large Telescope (ELT) will be the most powerful giant telescope in the world, with an M1 primary mirror of 39 meters in diameter. It will be 4 to 5 times larger than current equipment and collect 15 times more light.

ESO entrusted Safran Reosc with the polishing and testing of the 931 segments, each about 1.40 m width: 798 segments forming the M1 mirror and 133 spare segments.

The general concept of this project is to realize a modular telescope, which allows manufacturing parts in large quantities and considerably reduced costs.

To meet this industrial challenge, Safran Reosc has created a production plant in Poitiers, in which four Symetrie hexapods are installed: a hexapod is used to characterize the blanks of the segments, a hexapod positions the segments, a hexapod sets the reference and another hexapod aligns the deflection mirror at the top of the several meters tower.

The main characteristics of these hexapods are their very good resolution of 0.1 µrad and their excellent stability of 0.1 µrad over 1 hour, which required the creation of specific measuring tools.

Two of these hexapods incorporate a 360 ° turntable integrated in the mobile platform of the hexapod, while having a load capacity of 2 tons.

According to Laurent-Daniel Haret, ELT-M1 Safran Reosc metrology project manager, “we now have a set of machines on site that will allow us to position our optical parts with remarkable precision and stability. “

Built in Chile at an altitude of 3,046 m, the ELT will allow significant progress in astronomy (stellar archeology, discovery and characterization of exoplanets, etc.). Its “first light” is scheduled for 2024

For more information, please visit: https://symetrie.fr/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech