Universal Robots showcased its collaborative robots at the ATX East in New York City

Photo by Universal Robots ApS

Attendees at UBM’s ATX East in New York City, were greeted by three collaborative robots from Universal Robots at the expo entrance. Moving through pre-programmed cycles, the cobot arms equipped with monitors featured videos of a wide variety of industrial tasks now handled by Universal Robots – from CNC machine tending to polishing, wire cutting, injection molding and pick & place applications. As in many of their real life installations, the cobots were placed in a high-traffic area where they will operate with no safety guarding alongside people.

In this presentation “Getting the best ROI out of a Collaborative Robot” at the Smart Manufacturing Summit, Area Sales Manager with Universal Robots, Brian Dillman, presented best practices for working “hand in hand” with cobots in fast payback scenarios. “I look forward to sharing how cobots deliver greater interaction in a meaningful and productive way while benefitting both the work environment and the bottom line,” said Brian Dillman who also joined the panel “The Reality of What’s Possible with Collaborative Robots and What’s Still in the Works.”

On the expo floor, attendees could interact with the UR cobots at Universal Robots’ own booth at the ATX East section of the show where a UR5 robot arm was showcased in a new demo featuring collision avoidance and real-time adaptive pick & place with UR partner Energid, a developer of software for robots and machine vision. The UR5 picked ‘widgets’ out of a feeder that moves around and is dynamically tracked by the vision-guided cobot. Using a wand, a person can interact with the collaborative robot and the robot will avoid the wand while attempting to reach the widget.

“The ability for the robot to ‘dodge’ the wand is an example of what we believe will be the next generation of collaborative robots,” says CEO of Energid, Neil Tardella. “Soon, robots will be able to avoid collisions with people altogether rather than just stopping once a collision occurs. We believe that there is a large market for robots that can perform tasks in a semi-structured environment, where the requirement for precise positioning of fixtures and parts is relaxed, making setup and programming of the UR cobots even easier.” The Energid software is now also part of the rapidly expanding Universal Robots+ platform featuring plug & play products for the UR robot arms.

Robotic Vision Technologies demonstrated their new single-camera 3D guidance application for UR robots. The demonstration showed a UR5 picking randomly placed parts off a conveyor and precisely placing them in a moveable tray, in both 3D and 2.5D. “The demo highlights the flexibility that 3D vision brings to imprecise hardware or part presentation in automated assembly,” says Paul Weidinger, VP of Engineering at Robotic Vision Technologies. “With 3D vision, the UR can now be utilized in more applications, while keeping integration costs low.”

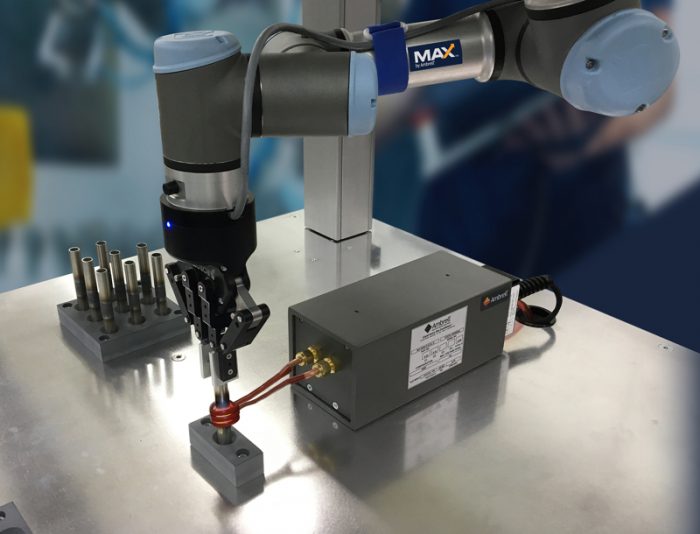

Also in UR’s ATX booth was MAX by Ambrell, the world’s first heat induction cobot. The demo at ATX East showed MAX moving stainless steel rods into an induction heating coil where the rods will be heated to 600 °C in just seconds by an Ambrell EASYHEAT induction heating system and then moved forward in the process. “An adaptation for this trade show demonstration could be preheating rods for hot heading or forging industrial fasteners, delivering an innovative induction heating solution designed specifically to maximize manufacturing throughput,” says Ambrell President, Tony Mazzullo. “MAX can perform a variety of light industrial – usually repetitive – tasks, and interacts safely and efficiently as it works hand-in-hand with humans in a shared process.”

Another repetitive task now automated by UR cobots is passport stamping; attendees visiting the UR booth, participating in the show’s “Passport Tour”, could get their passport stamped by a cobot and then entered into a daily prize drawing.

At booth #2644, READY Robotics showcased the TaskMate system, a fully-integrated turn-key solution which incorporates the Universal Robots collaborative robot line. The TaskMate R3, utilizing a UR3 arm, showed the system flexibility through a series of dynamic interactive demonstrations. “READY Robotics is working to change the way customers approach robotic automation by providing a fully plug-and-play platform architecture allowing customers to easily build whatever automation system they need for a given application,” said Ben Gibbs, CEO of READY Robotics. “By integrating with Universal Robots, we are able to leverage tremendously useful robot hardware to further reduce the integration overhead customers and integrators experience in trying to address their automation application needs.”

Brian Dillman was excited to share these applications with the ATX East audience: “We see a collaborative robot as a tool on demand as needed – one that can quickly be transitioned between a wide variety of automated tasks. Flexibility in manufacturing involves ability to deal with variation in volumes, design and material handling as well as variations in the process sequences. We look forward to showcasing these important capabilities at the show,” says Brian Dillman.

For more information, please visit http://www.universal-robots.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech