NEWS HOME » Metalworking

BIG-PLUS spindle and tooling systems can now be produced by three more manufacturers

BIG KAISER, a leader in premium high-precision tooling systems and solutions for the aerospace, automotive, energy, medical and watch-making industries, announces that three more industry-leading machine manufacturers – Hurco, Spintrue and OMV […]

HEULE’s BSF Back Spot Facing Tool utilized by Korean jet-engine manufacturer for gas turbine machining

The aircraft industry is known for its need for most reliable solutions. So a Korean jet-engine manufacturer who uses the BSF Back Spot Facing Tool for the spot facings on its gas […]

Pokolm further innovates its cutting material packaging

Pokolm proves its high claim to superiority even in the details of its cutting material packaging. At first glance it might be thought that cutting material packagings are only important for transport, […]

Meusburger adds new group ‘Active parts’ to its range of die making products

The standard parts manufacturer Meusburger is expanding their range of products in the field of die making with the new group ‘Active parts’. These are all products which are in direct contact […]

Ganter develops new solutions for easier and more effective installations

Hinges are used to mount hatches and doors, and their installation and any resulting problems can be just as varied as the uses of the hinges themselves. In many cases Ganter offers […]

Sandvik Coromant’s CoroCut QD with new smaller insert widths helps reduce expensive material waste

When material savings is a requirement due to machining expensive materials, large batch productions, or both, it is essential to use the thinnest insert width possible. CoroCut® QD dedicated parting off and […]

Walter’s new M4000 system inserts offers maximum cost efficiency for milling operations

With its M4000 family, Walter has made huge advances towards achieving maximum cost effectiveness in milling. The M4000 system inserts can be used in a variety of tools, which means that they […]

Meusburger’s new E 6570 Terminal block allows multiple limit switches checking simultaneously

With the new E 6570 Terminal block for limit switches from Meusburger, it is possible to check several limit switches on the machine at the same time with only one connector. Therefore […]

EMAG discusses the benefits of solid-state lasers over standard CO2 lasers for welding applications

Even a few years back major manufacturers utilized standard CO2 lasers in factories for welding applications. Massive systems installed in separate rooms away from the actual production process supplied the energy for […]

Kaltenbach’s KPS-A 167 now able to perform circular cutting

The KPS-A 167 now has a circular cut option. With angle steel the circular cut is made on one of the material legs – the primary leg. In order to prevent deformation, […]

POKOLM’s new Doubletriga features cutting edge design with maximum efficiency

With Doubletriga, the engineers from POKOLM – the East Westphalian specialist for premium tools in the field of milling technology – are providing users with a genuine universal genius made with a […]

Hainbuch clamping devices provide the right solutions for KTR Group

Off to new horizons – with new machines, shorter processes, and a new workholding technology at the KTR Group in Rheine. During the periodic replacement of the machines the clamping devices were […]

Meusburger introduces optimised standard for insulation boards with 0.02 mm parallelism

The steadily increasing quality requirements in mould making demand the highest manufacturing precision from the standard parts manufacturers. This applies not only to moulding plates but also to insulation boards. Therefore Meusburger […]

Walter included solid carbide milling cutters range to its Perform line for the first time

With the MC232 Perform product line, Walter is adding to its range of solid carbide milling cutters. Three new cutter types, with 2, 3 or 4 teeth, in a diameter range of […]

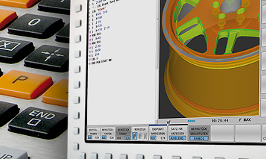

HELLER successfully demonstrated perfect coordination of its production facilities from multiple countries

Specific projects prove that the HELLER locations are increasingly acting as a team. “The so-called 6F15 Project clearly demonstrates how well the HELLER production facilities around the globe are coordinated and bringing […]