Induction hardened Rollon linear bearings for high cyclic heavy duty applications

The advantages of induction-hardened Rollon linear guides in high-cycle heavy-duty applications.

Linear technology for heavy loads and high numbers of cycles places special demands on load capacity, wear resistance and resistance to deformation. Induction hardening is the technology of choice here. Rollon, a specialist in linear motion systems, has perfected this demanding process over decades and supplies linear guides with induction-hardened raceways that meet the highest demands in terms of quality, durability and reliability.

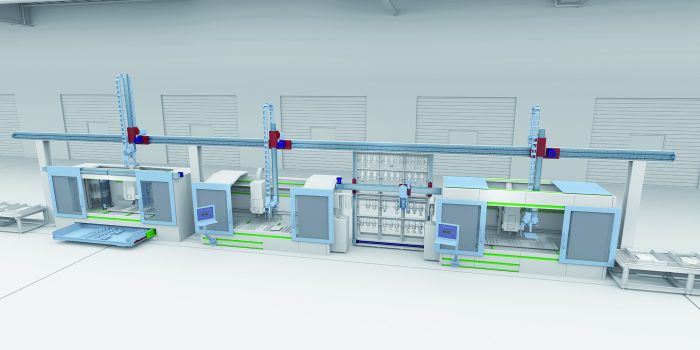

Whether in warehouse automation, robot cells, rail vehicles or machine tools: linear guides in industrial automation and heavy-duty applications are often exposed to high mechanical loads and must meet high requirements in terms of robustness, durability, dynamics and performance.

A high degree of hardness is of decisive importance here, because the lower the surface of the raceways is hardened, the more susceptible they are to damage. Insufficient hardness depths also have a negative effect on load capacity. Thus, rails with thin hardened edge layers tend to crack quickly under load. This is due to the position of the maximum stress (Hertzian pressure) between roller or ball and rail. This is not located on the surface, but underneath – and at a depth that many hardening processes do not reach.

Induction hardening makes the difference here. Heat treatment allows great hardening depths and penetrates into the areas of maximum stress. The result is a particularly hard and wear-resistant surface. Induction-hardened guide systems can thus achieve high running performance without damaging or deforming the raceways.

Induction-hardened and ground raceways from Rollon as one of the world’s leading full-range suppliers of linear technology. Rollon is an absolute specialist in the induction hardening of raceways and has extensive expertise and years of experience.

In induction hardening, the area of the steel to be hardened is first heated inductively, i.e. by means of an electromagnetic field, and then quenched. This causes the microstructure to undergo a martensitic transformation and, as a result, a considerable increase in hardness. To achieve maximum hardness Rollon uses only high quality steels with a high carbon content. Immediately after induction hardening, the surface can be machined and the surface quality and thus the frictional properties can be improved by grinding or honing

Induction hardening: The solution for maximum performance

The Rollon rails achieve Rockwell hardnesses between 58 and 62 HRC and hardness depths of around 1.2 mm. Induction-hardened and ground Rollon tracks are heavy-duty, low-maintenance and extremely durable, enabling significant performance improvements in industrial and heavy-duty applications.

For more information, please visit: https://www.rollon.com/DE/de/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech